Best Membrane Filtration System Manufacturer

Neologic Engineers is emerging as the reputed spiral would membrane filtration system manufacturer in India. Spiral would membrane filtration is known for its design which offers the most advanced cross-flow membranes. These membranes are usually divided into:

- Microfiltration (MF)

- Ultrafiltration (UF)

- Nanofiltration (NF)

- Reverse Osmosis (RO)

Neologic Engineers provides unique solutions to both customized membrane filtration plant as well as complete process lines. Our solutions are specifically tailored to meet the needs of our clients in the dairy, food, and beverage industry.

Membrane Technology in Food Processing Industry

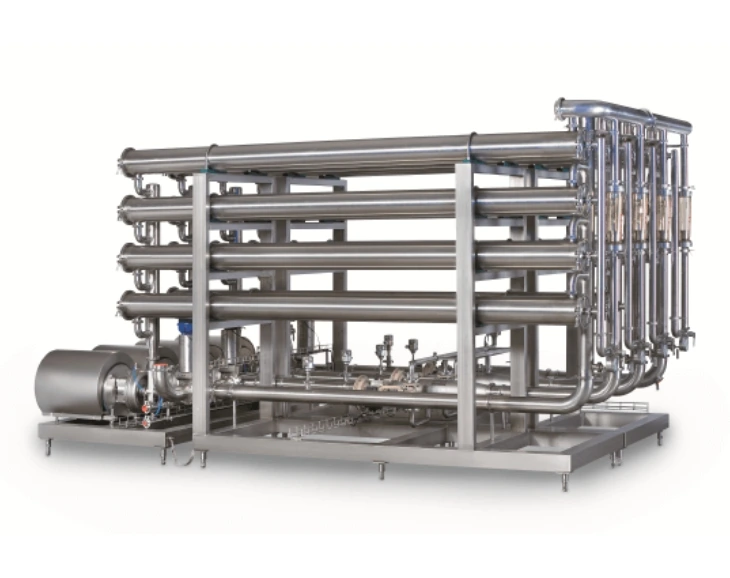

Neologic Engineers membrane filtration units have a compact, hygienic design for easy cleaning. They are designed to process your products safely. Apart from giving the right performance in terms of Mass Balance, we design the membrane filtration units to have the lowest power consumption and cleaning chemicals. Our cross-flow membrane filtration pilot units are available to test any application, including clarification, bacteria and spore removal, fractionation, concentration and/or separation including diafiltration, in the food and beverage, dairy, and fermentation industries, on-site or at our test centers. NB: Our test centers are located at Alfa Laval Denmark.

Neologic Engineers Offers Different Membrane Filtration System

As an industry-leading provider of equipment to the dairy and food processing industries, at Neologic Engineers, we can design and manufacturing custom fluid separation systems for a variety of applications.

Fluid separation systems remove microorganisms, fats, proteins, or carbohydrates from raw milk or other feedstock streams. Different membranes are used to effectively remove each type of particle based on its size.

A separation system is designed with the necessary microfiltration, ultrafiltration, reverse osmosis, or nanofiltration system to create the needed streams for processing. The equipment is manufactured to the highest quality and sanitation standards using durable materials that are easy to clean and require minimal maintenance.

Different Membrane Types

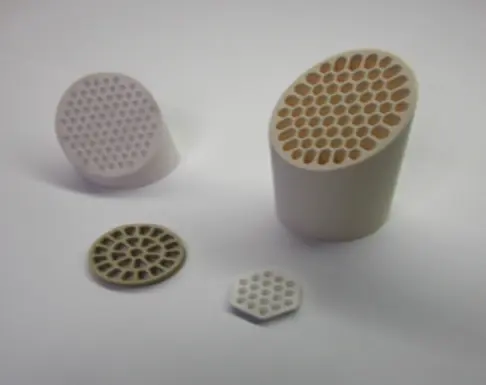

Membranes are selected to meet the specific requirements of the application in question. The range of membranes can be split into two main groups - polymeric (organic) and ceramic (inorganic).

Polymeric membranes include a range of different membrane types such as spiral wound, hollow fiber and flat sheet (plate-and frame) membranes - all of which are made from organic materials. Polymeric spiral wound membranes provide a high membrane area per element, leading to a reduced footprint and cost-efficient plant designs. Cleaning of these types of membranes requires specially formulated cleaning detergents to extend their lifetime. As polymeric membranes come in a wide range of pore sizes, they can be used for a large number of dairy filtration applications from RO to MF.

Ceramic membranes include a number of membranes which are all made from inorganic materials. As ceramic membranes are very resistant to temperature and chemicals, they are easy to clean. The lifetime of ceramic membranes is longer than that of polymeric membranes. Compared to polymeric membranes, ceramic membranes have a much higher flux, but to do their tubular design, they have less membrane area per element. Ceramic membranes come in a limited range of pore sizes, and are normally used for microfiltration and in some cases ultrafiltration processes.

Processing Units for Each Application

Neologic Engineers provides membrane filtration units specifically tailored to meet your needs and requirements.

With our extensive theoretical and practical experience together with Alfa Laval Denmark, within membrane filtration along with our well-defined standard modules, we are able to design membrane filtration units for all membrane filtration applications within the dairy & food industry.

Our breadth of membrane filtration equipment means that we can be with you from initial testing on pilot units to small standardized units and, ultimately, custom-designed full-scale production, while meeting local regulations. Our unique plant sizing software works to identify the optimal plant configuration.

The “Plug-and-Produce” unit philosophy provides our customers with several benefits such as space-saving designs, seamless integration and short installation time. We are able to deliver membrane filtration solutions with low energy consumption and noise emission and reduced product and detergent waste.

Why Choose Us as Your Membrane Filtration System Manufacturer?

To help avoid the risk of a breakdown, Neologic Engineers focuses on preventive maintenance and regular service to keep your plant and equipment running, saving you from potentially expensive downtime. Neologic Engineers supports and supplies replacement membranes and parts for all known membrane filtration technologies including microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Organic membranes have a limited life span and typically need replacement once or twice per year (depending on the processing rates and conditions) to maintain consistent performance of the unit. The most significant factor affecting the performance of membrane processing systems is membrane fouling. It is the result of insoluble materials coating the membrane surface and causing a reduction in product quality.

Neologic Engineers together with Alfa Laval stocks replacement membranes and works with each service technician to maintain a service replacement history and predict when new membranes will be needed. With Neologic Engineers, you can count on dedicated service specialists to make service optimization visits on request, carry out a follow-up of the installation and its parameters, or provide staff training.

Where membrane filtration is a part of a processing plant, its role is key to the efficiency of the plant. It is therefore essential to maintain membranes diligently to maximize profits and keep them in top operating condition. Neologic Engineers offers an innovative membrane lifetime extension program Perform ‘Up. Perform ‘Up is a performance program with regular process, hygiene and quality checks. By analyzing the specific membrane fouling compensation, we are able to recommend a customized clean-in-place (CIP) program to improve overall production performance and reduce TCO.

Frequent Searches: Membrane Filtration System Manufacturer, Best Membrane Filtration System Manufacturer, Membrane Technology in Food Processing Industry